Fiber Laser Printer Machine Price

Fiber Lasers of Gulf States Saw & Machine Co. can provide precise and consistent metal cutting.

The laser module can engrave with a repeatable precision of +-0.00039" and a life expectancy of 100,000+ hours.

Laser cutting fibers can significantly improve the productivity of metal fabrication shops or companies manufacturing custom-made metal parts.

With the CNC control system, the fiber laser cutter is equipped with a laser generator to dope the pump material into the optical fiber, and the laser of a specific wavelength emitted by the semiconductor laser is coupled to make the optical fiber generate laser light. Then, the machine converges the laser beam into a small diameter spot to form a beam of high energy density and extremely bright light, which acts on the metal to be cut, which causes the temperature of the metal at the laser irradiation point to be sharp it rises and reaches the vaporization temperature instantaneously, causing evaporation and forming holes. And the machine uses this as the starting point, according to the shape requirements of the part to be cut, the laser beam and the part are moved relative to each other according to a certain trajectory to form a slit. At the same time, the auxiliary gas blowing device is used to remove the slag.

FSL Muse Pandora may be upgraded to include a rotary Axis, Z-travel expansion, fume extractors and special focus lenses.

Other options include 6.9"x6.9", 5.9�x5.9�, 4.3�x4.3�, 2.6�x2.6� and 2.6�x2.6�. They can be chosen depending on the operational need.

Fiber Lasers of Gulf States Saw & Machine Co. can provide precise and consistent metal cutting.

The laser module can engrave with a repeatable precision of +-0.00039" and a life expectancy of 100,000+ hours.

MCWlaser PRO split-type machines are those that have both the laser source or the engraving device in separate parts.

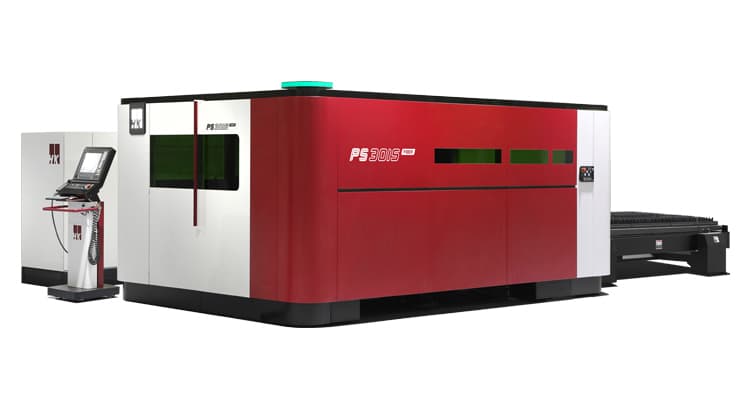

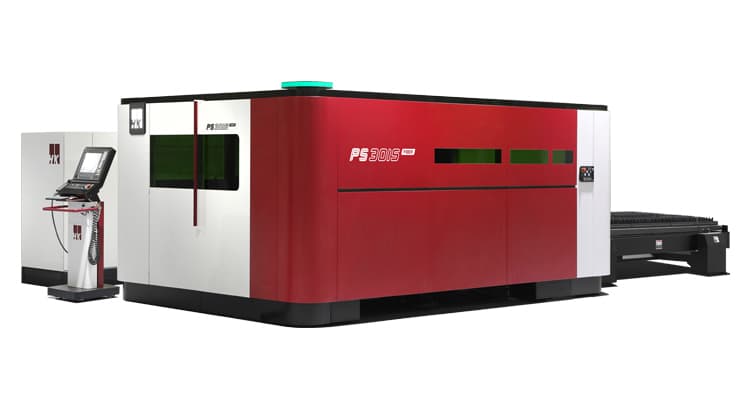

A large-sized fiber laser that brings fine, high-precision processing to projects of nearly any size.

We offer a variety of laser power options, including 1000W, 1500W. 2000W. 2500W. 3000W. The fiber laser machines have a cutting speed up to 35 m/min. This allows them to complete jobs quickly and with high precision. Laguna Tools also offers machines with enclosed areas that eliminate light pollution.

Fiber lasers are popular for engraving metals, as they can engrave much more accurately than generic CO2 Lasers.

MOPA fiber laser is a special type of fiber laser that allows for greater control over the pulse width and frequency parameters. This laser can be used to color laser engravings on metals.

FSL Muse Pandora is able to raster or vector engrave aluminum, steel and nickel as well as silver, titanium, copper, and stone.

Fiber lasers are revolutionizing laser metal cutting industries with their low maintenance costs, high cutting efficiency and lower cost.

The closer M2 values are to 1, the more laser energy is delivered to the laser spot. It allows for the processing of thicker materials, with deep wells that are thin.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Laser fiber cutting machine

Fiber optic laser cutters are intended to cut metal at high speeds and with pinpoint accuracy. These machines, which have been on the market for more than 20 years, also use a fiber laser power source.

Marking and engraving are improved by high peak power and nanosecond pulses. The increased power and improved beam quality result in cleaner cut edges and faster cutting speeds. Fiber lasers are also used in material processing, telecommunications, spectroscopy, medicine, and directed energy weapons.